Guide to the safe loading, storing, lifting (LOLER) and testing of stillages

Stillages, especially when laden, are very heavy. Therefore, it’s important that they are loaded, moved and transported safely at all times. If you intend to lift your stillages using a forklift or crane, please carefully read the information below.

Remember that most of our stillages can be manufactured using industrial castor wheels for improved mobility without the need for lifting with equipment. Please discuss your stillage requirements with us before placing your order or call us for further advice.

This guide is divided in to 2 parts:

1. I want information about the safe loading, storing and forklift lifting of stillages (CLICK HERE)

2. I want information about the safe crane lifting of stillages (CLICK HERE)

1. Guide to safe loading, storing, and forklift lifting of stillages

Our range of stillages and post pallets are manufactured to be durable and long-lasting. Please review the table below for information regarding loading and storage.

Please note that the following table is for STANDARD PRODUCTS only. Changing the products specifications (e.g. replacing standard feet with castors) may alter the SWL (Safe Working Load) and/or the Safe Stacking Height. See individual product pages for further information.

We recommend that products intended to be lifted by forklift are fitted with forklift pockets. This is a low cost option available on most of our products. See individual product pages for further information.

| Scroll right to see more --> | |||

|

Product name |

Product Code |

Safe Working Load |

Safe Stacking Height* |

|

Metal Stillage with Solid Sides |

SS01 |

1000KG |

4 |

|

Double-Width Stillage with Solid Sides |

DWSSSB

|

1000KG

|

4 |

|

Large Lockable Site Box |

LSWL |

1000KG |

4 |

|

Large Lockable Site Box with Mesh Inserts |

LSHDFMI |

1000KG |

4 |

|

Metal Stillage with Solid Sides and Half Drop Front Door |

HDSS01 |

1000KG |

4 |

|

Metal Stillage with Solid Sides and Detachable Front |

DSS01 |

1000KG |

4 |

|

Large Lockable Site Box with Half Drop Front |

LSHDFWL |

1000KG |

4 |

|

Metal Stillage with Fixed Internal Partitions |

SSFP01 |

1000KG |

4 |

|

Metal Stillage with Half Drop Front Door (XL) |

HDHD01 |

1000KG |

4 |

|

Metal Stillage with Open Front |

OFSS01 |

1000KG |

4 |

|

Metal Stillage with Removable Partitions |

SSRP01 |

1000KG |

4 |

|

Chute Storage Stillage |

MC01 |

1000KG |

4 |

|

Double Width Lockable Site Box with Half Drop Front |

DLSHDFWL |

1000KG |

4 |

|

3 Sided Chute Stillage with Tilted Base |

STB |

1000KG |

4 |

|

Metal Stillage with Mesh Sides |

MS01 |

1000KG |

4 |

|

Double Width Stillage with Mesh Sides |

DWMSSB |

1000KG |

4 |

|

Foldable Pallet Cage |

GFWMS01 |

800KG |

4 |

|

Metal Stillage with Mesh Sides and Detachable Front |

DMS01 |

1000KG |

4 |

|

Combined Post Pallet Rack and Storage Cage |

CPPMS |

1000KG |

4 |

|

Metal Stillage with Mesh Sides and Open Front |

OFMS01 |

1000KG |

4 |

|

Metal Stillage with Mesh Sides and Half Drop Front |

HDMS01 |

1000KG |

4 |

|

Gas Bottle Cage for Argon Gas Bottles |

GCA |

N/A |

N/A |

|

Metal Stillage with Mesh Sides and Hatch Door |

MSHD01 |

1000KG |

4 |

|

Metal Stillage with Solid Sides, Shelf and Double Drop Front Doors |

DDSS01 |

1000KG |

4 |

|

Metal Post Pallet with Demountable Legs |

DMPP01 |

1000KG |

4 |

|

Budget Post Pallet with Demountable Legs |

DMBPP01 |

1000KG |

4 |

|

Budget Metal Post Pallet |

BPP01 |

1000KG |

4 |

|

Demountable Metal Post Pallet (Heavy Duty) |

DHPP01 |

1000KG |

4 |

|

Metal Post Pallet with Solid Base |

PPSB01 |

1000KG |

4 |

|

Demountable Metal Post Pallet (Heavy Duty) with 1.3 Legs |

DHPP02 |

1000KG |

4 |

|

Metal Post Pallet |

MPP01 |

1000KG |

4 |

|

Post Pallet Rack/Storage Cage (2 Bay) |

PMSS |

1000KG |

4 |

|

Post Pallet Rack/Storage Cage (3 Bay) |

PMSS |

1000KG |

4 |

|

Double Width Metal Post Pallet |

DWMPP01 |

1000KG |

4 |

|

Basic Metal Post Pallet (Unpainted) |

PPS01 |

700KG |

4 |

|

Galvanised Metal Post Pallet/Demountable |

GMPP |

1000KG |

4 |

|

Galvanized Metal Post Pallet/Demountable |

ZGPP01 |

1000KG |

4 |

|

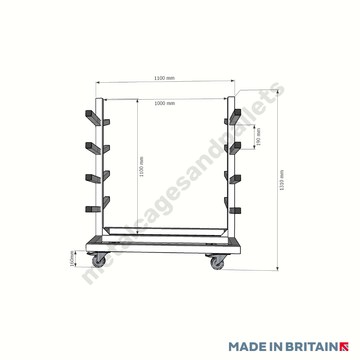

Reel, Carpet and Pipe Post Pallet |

HDTT |

1000KG |

4 |

|

Trestle Stands |

HDT |

1000KG |

n/a |

|

A Frame Stillage (Short) |

AFS |

1500KG/3000KG** |

n/a |

|

A Frame Stillage (Tall) |

AFSH |

1500KG/3000KG** |

n/a |

|

Pipe Trolley |

PRR |

750KG/1000KG** |

n/a |

|

Double-Width Pipe Trolley |

DWPT |

750KG/1000KG* |

n/a |

|

Pipe Trolley with Demountable Legs |

PRRD |

750KG/1000KG** |

n/a |

|

Trikke |

AC01 |

750KG/1000KG** |

n/a |

|

2-Tier Table Trolley |

HDTTT |

750KG/1000KG** |

n/a |

|

Industrial Trolley (Mesh Sides) |

HDMTT |

750KG/1000KG** |

n/a |

|

Stock Trolley |

SST |

750KG/1000KG** |

n/a |

|

Pipe Trolley (Mesh Shelves) |

HDTTM |

750KG/1000KG** |

n/a |

|

Panel Trolley |

SPBT |

750KG/1000KG** |

n/a |

|

Distribution Trolley |

HDDT |

750KG/1000KG** |

n/a |

|

Platform Truck |

HDPT |

750KG/1000KG** |

n/a |

|

Platform Truck (heavy duty) |

HDPTT |

750KG/1000KG** |

n/a |

|

Connecting Pipe Trolley |

CPRS |

750KG/1000KG** |

n/a |

|

Cantilever Trolley |

CT1 |

300KG |

n/a |

|

Pipe & Bar Trolley |

HDMPR |

750KG/1000KG** |

n/a |

|

UK Pallet Trolley |

UKPT |

750KG/1000KG** |

n/a |

|

Euro Pallet Trolley |

EPT |

750KG/1000KG** |

n/a |

|

Drum Dollly |

DD |

750KG/1000KG** |

n/a |

|

Pipe & Rod Storage Rack |

HDSR |

1000KG |

n/a |

|

FIBC Hopper for Forklifts |

BBFH |

n/a |

n/a |

|

FIBC Filling Hopper |

BBFH2 |

750KG/1000KG** |

n/a |

|

Stillage Hopper (x4 Chute) |

SFH2 |

n/a |

n/a |

|

Stillage Hopper |

SFH |

750KG/1000KG** |

n/a |

|

FIBC Frame |

PPBHSB01 |

1000KG |

n/a |

|

FIBC Frame (Demountable Legs) |

DBBH |

1000KG |

n/a |

|

Drum Stillage |

SDR |

1000KG |

n/a |

|

Forklift Gas Bottle Handler |

FGBH |

1000KG |

n/a |

*Please note that the total stacked load should not exceed the Safe Working Load of that product.

**Depending on castor fitted

2. Guide to safe crane lifting of stillages (LOLER)

We also have a range of stillages that have been specifically designed to be lifted or lowered by crane.

These stillages, along with any applicable lifting accessories (e.g., lifting eyebolts and/or shackles) are thoroughly examined by our authorised testing and examination team.

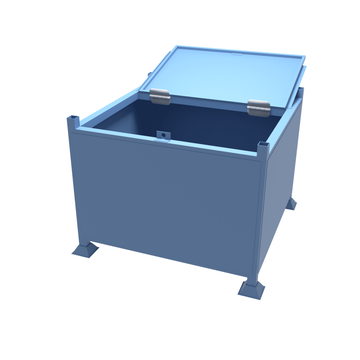

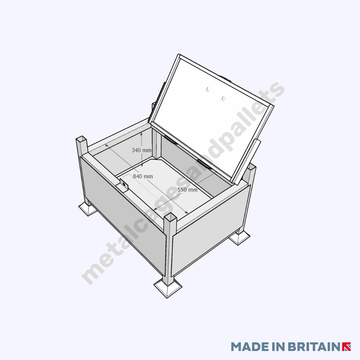

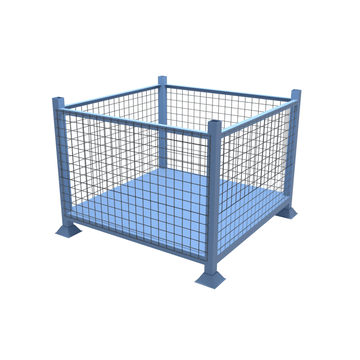

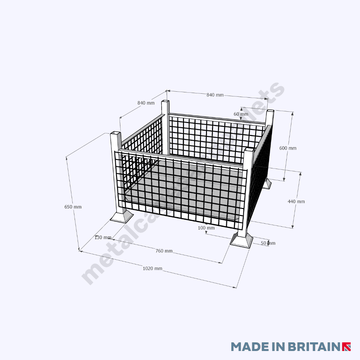

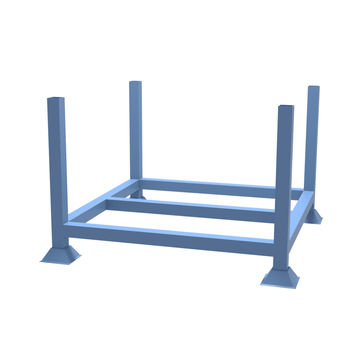

Example images of stillages that are suitable for lifting:

Crane Lift Stillage with Solid Sides.

Crane Lift Stillage with Mesh Sides.

Please ensure that you select the right stillage to suit your needs. If you are unsure, or if you need a product manufactured to your own specifications, please contact us prior to ordering.

| Scroll right to see more --> | |||

|

Product name |

Product Code |

Safe Working Load |

Safe Stacking Height* |

|

CL-AFS |

1000KG |

n/a |

|

|

FIBC Lifting Jib |

BBLJ |

1000KG |

n/a |

|

FIBC Lifting Frame |

BBLF |

1000KG |

n/a |

|

Forklift Mounted Jib |

FMJA |

1000KG |

n/a |

|

Forklift Spreader Beam |

FLSB |

1000KG |

n/a |

|

Forklift Lifting Hook |

FLH |

1000KG |

n/a |

|

CL-MS01 |

1000KG |

4 |

|

|

CL-DWMSSB |

1000KG |

4 |

|

|

CL-DWSSSB |

1000KG |

4 |

|

|

Metal Half Drop Front Stillage |

HDMS01 |

1000KG |

4 |

|

Mesh Stillage & Detachable Front |

DMS01 |

1000KG |

4 |

|

Mesh Stillage & Hatch Door |

MSHD01 |

1000KG |

4 |

|

Metal Stillage, Solid, Detachable Front |

DSS01 |

1000KG |

4 |

|

Metal Stillage, Solid, Half Drop Front |

HDSS01 |

1000KG |

4 |

|

CL-SS01 |

1000KG |

4 |

|

|

Half Drop Front Solid Stillage |

HDHD01 |

1000KG |

4 |

|

Metal Stillage Fixed Partitions |

SSFP01 |

1000KG |

4 |

|

Metal Stillage Removable Partitions |

SSRP01 |

1000KG |

4 |

|

Chute Stillage |

MC01 |

1000KG |

4 |

|

Metal Stillage Double Drop Front |

DDSS01 |

1000KG |

4 |

|

Lockable Site Stillage |

LSWL |

1000KG |

4 |

|

Lockable Site Stillage/Drop Front |

LSHDFWL |

1000KG |

4 |

|

Lockable Site Stillage/Mesh |

LSHDFMI |

1000KG |

4 |

*Please note that the total stacked load should not exceed the Safe Working Load of that product.

Thorough Examination of lifting equipment

Once our lifting products have been manufactured, each product is thoroughly examined by our team which have completed training in the Thorough Examination of Lifting Equipment Accessories. Training was delivered by Lloyds British (Speedy Group) in May 2021. Copies of our training certificates can be issued on request.

Our thorough examination of lifting equipment includes the following component checks:

- Condition and structure of the product

- SWL (Safe Lifting Weight) markings clear and securely attached

- Serial number markings clear and securely attached

- Feet

- All welds complete

- Cracking of welds

- Floor plate

- Lifting points

Once the products have been thoroughly examined our certified team will then issue a “Report of a Thorough Examination and Test of Lifting Equipment” certificate. This certificate is issued in accordance with the Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) Schedule 1.7 and The Provision and Use of Work Equipment Regulations 1998 Regulation 6.

This certificate will include the following information:

- Certificate issued by (Prospect Engineering (MIA) Ltd t/a Metal Cages & Pallets)

- Issued to – your company name as per your billing address

- Tag ID – this is the Identification Mark of the Equipment, and will contain a unique ID number

- Description of equipment, and any additional accessories supplied

- Number of units examined

- Safe Lifting Weight/Working Load Limit

- Date of next Thorough Examination (6 months from first examination date)

ID/Marking of lifting equipment

Each product will then be given a unique tag which is fixed to the product. This tag will include the following information:

- ID number

- SWL (Safe Lifting Weight) in KG

- Test date

Safe use of lifting equipment

Once your products have arrived, we recommend that you first give the products a thorough examination (this should be done by a competent person) to check for possible damage during transit.

Once in use we recommend that you regularly inspect the products, keeping your own records of any through examinations made.

- We do not recommend that our stillages (empty or laden) are lifted using straps.

- We recommend that you have a Safe Lifting Policy in place, and that your employees and contractors are trained accordingly.

- You should ensure that your stillages are inspected by a competent individual on a regular basis.

- Once the testing certificate expires, you should not allow your stillages to be lifted

For further guidance please visit the HSE website:

https://www.hse.gov.uk/work-equipment-machinery/loler.htm

Re-testing of lifting equipment

Our through examination certificates expires after 6 months from the date of the first examination.

Once the product reaches this date you have the following options:

- Destruction, or discontinue lifting (we also recommend that any lifting eyebolts or lifting fixings are permanently removed so that the product can no longer be used for lifting)

- Re-test. We are able to offer a UK service to thoroughly examine lifting products sold by ourselves every 6-months. Please contact us for further information