How is a stillage made? – Metal Stillages, Cages & Pallets

How is a stillage made?

How is a heavy-duty stillage made by MC&P to be tough, strong and hardwearing?

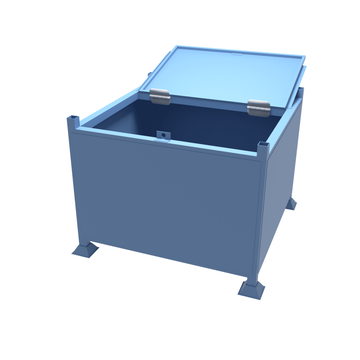

Used across a huge range of sectors and industries, stillages need to be well constructed, in a sturdy material that’s strong enough to hold generous load capacities, making them versatile even in the most demanding working environments.

Different stillage designs by MC&P take these factors into account, adding extra features and custom options as required to create stable metal stillage frameworks that are made to last, no matter the loads they carry.

This article looks at how a stillage is made by MC&P to suit your organisation’s needs while offering excellent value for money.

How is a stillage made to be strong?

MC&P stillages are designed and engineered for heavy-duty uses, suiting demanding sectors from construction and forestry to logistics, manufacturing and warehousing. A stillage is made to be strong using tough mild steel that’s good to work with and will make a stillage that’s built to last.

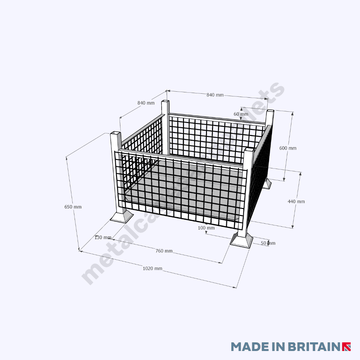

Stillages made by MC&P are strong and robust, withstanding tough working environments as a result of their construction using materials such as box section steel instead of angle steel, giving additional reinforcement to corners and legs which allows stillages to carry greater capacities whilst remaining stackable.

How are MC&P’s stillages made?

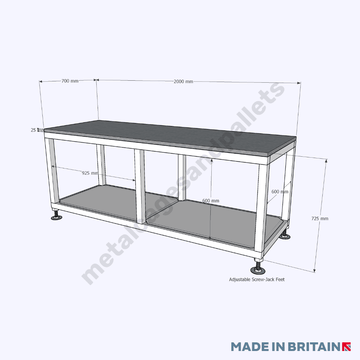

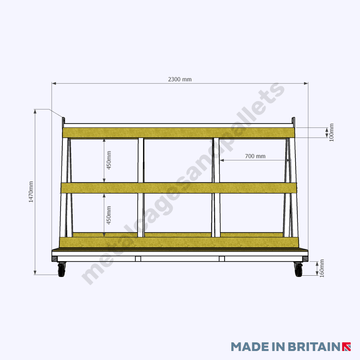

How are strong, versatile stillages made by MC&P for use across any sector? Our processes are tried and tested by a team with over 35 years’ experience in metal stillage, cage and pallet engineering.

Key to how a stillage is made is the strength of the complete structure, and its ability to remain stable, even when fully loaded, and to be moved either manually or mechanically using a pump trolley, forklift truck, hiab or telehandler – or even a crane.

A stillage is made by MC&P in a number of stages:

- Standard stillages bought online are often already in stock, made in our factory ready for distribution across the UK.

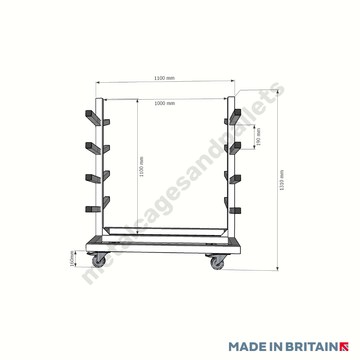

- Stillages are made to a standard design and specification, but can be customised with options such as the addition of forklift guides for safe mechanical lifting, or castor wheels, for safe, mechanical-free handling by your team.

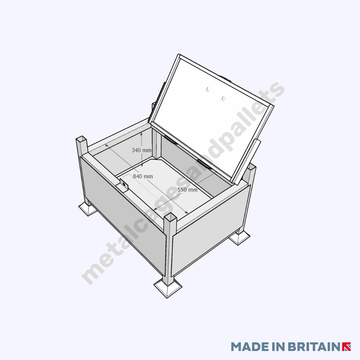

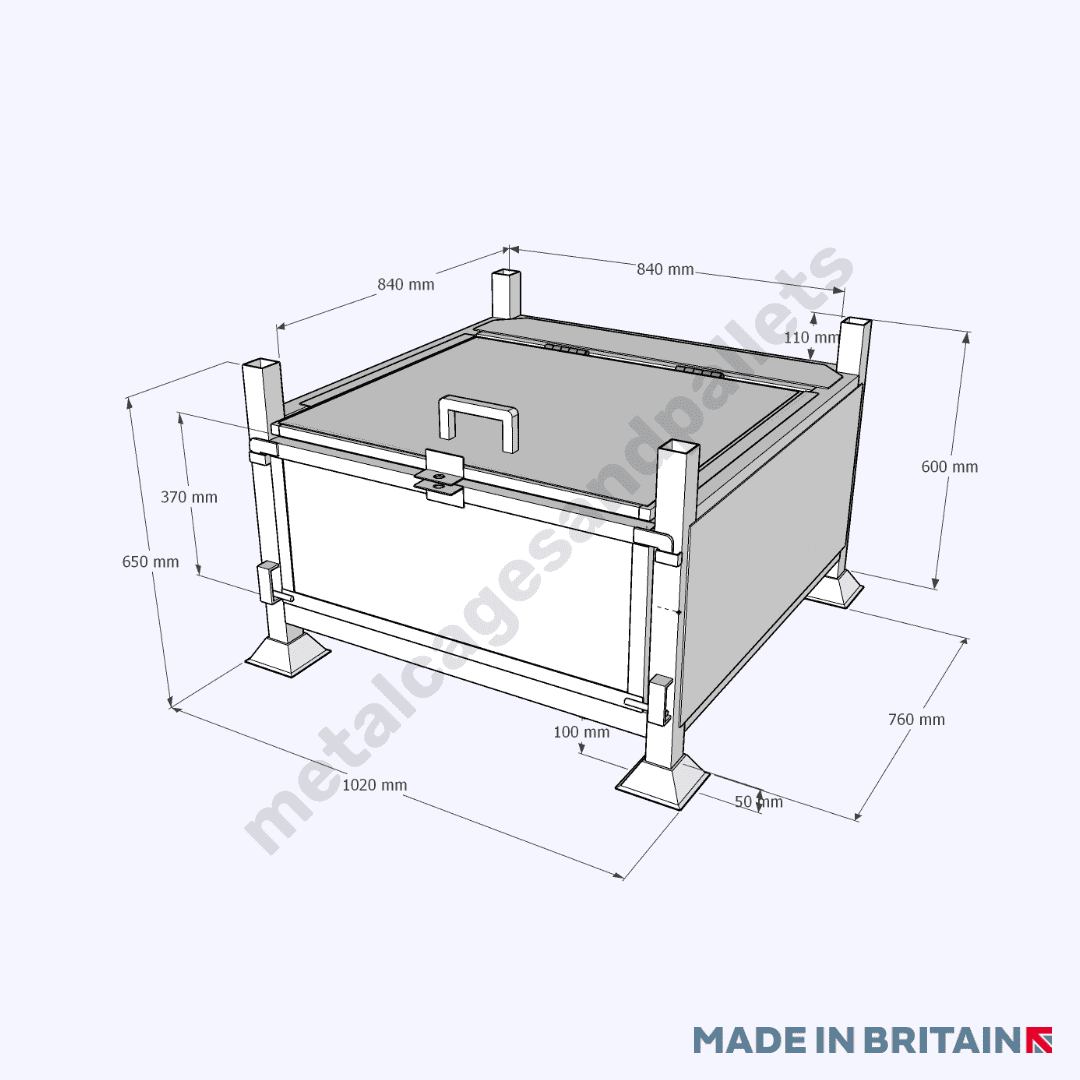

- A customised stillage is made bespoke. When you contact our team to discuss what you need from your stillage, we will agree how your product can be made to suit your operational needs – for example, should it be a different shape or size, does it need to feature access hatches or drop-doors, or does your stillage need to be made with other features to keep goods secure during handling, storage or transit?

- Fully-welded stillages made by MC&P mean no self-assembly, nuts or bolts are required. You’ll receive a fully-assembled, strong stillage that’s ready to get to work straight away, and has been quality-checked by our team before leaving the factory.

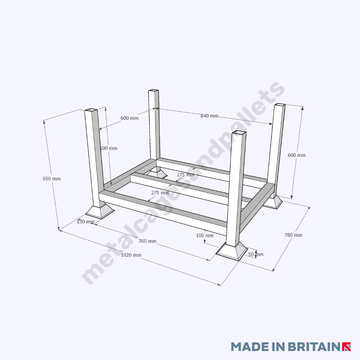

- Stillages are made with pressed feet, giving stillages made by MC&P superb strength and stability when in transit, storage or when stacked. Feet are “pressed” from a single sheet of steel, ideal for heavy-duty stillages made to carry demanding loads.

- Whether standard or bespoke, stillages made by MC&P are designed and engineered in-house for reassurance that your stillages will be made, quality-assured and shipped without delays.

- MC&P stillages are made in our UK factory and shipped nationwide by trusted couriers, or collected by you direct from our factory. When you buy from us, you’re buying British engineering from a family-run business with years of experience in stillage engineering.

How a stillage is made is often determined by how the stillage will be used. For example, do the contents need to be easily visible or accessible via a hatch door or drop side, will contents be heavy and does the stillage therefore need to weigh less, will contents be valuable, requiring a lockable stillage, and where will the stillage be stored?

MC&P’s versatile stillage range is made to suit almost any working environment you can think of, but customised stillages can be designed and engineered bespoke if you need something unique.

Click here to read our Stillage buyers guideHow are stillages made to last?

MC&P stillages are made to be strong, tough and hardwearing, suiting a vast range of heavy-duty applications. In particular, MC&P only uses box section steel when constructing our stillages, cages, pallets and other handling products. When considering how a stillage is made, it’s important to look at whether stillage frames are made from box section or angle steel.

- Box section creates strong, reinforced stillages, storage and logistics systems that are tough, longer-lasting and used by organisations that need durability, reliability and excellent load capacities from their stillages.

- By contrast, angle steel features an L-shaped cross-section formed by bending a sheet of steel at a 90-degree angle.

Angle steel may be used to create framing, bracing and supports in some structures, but the square shape of the box section offers superior rigidity and strength – in fact, steel box section is at least 100% stronger than angle steel. Angle steel carries less structural integrity due to its open shape, limiting stacking ability, longevity and reliability.

MC&P chose box section steel when deciding how our stillages would be made because we know our products will offer unbeatable strength and durability, not only carrying excellent capacities but saving space in your working area thanks to their “stackability”.

Click here to find out how long a stillage will lastHow is a custom stillage made to suit your organisation’s operations?

Custom stillages are made by MC&P to the unique requirements of your organisation and your sector. Stillages from our standard stillage range can be bought online and customised to suit your operations with options such as:

- Castor wheels, for mechanical-free handling and movement around your workplace

- Forklift guides, for safe mechanical lifting

- Additional steel bracing to make a stillage with extra strength

- Different sizes, to suit the storage and handling of longer-length products

- Additional height to stillage sizes, accommodating taller products

How does MC&P make crane lifting stillages? Crane lifting stillages adapt our standard stillage designs for the safe lifting and lowering by crane, adding crane lifting eyes and lugs to the structure of the stillage before being thoroughly examined by our trained and qualified team.

Crane lifting stillages made by MC&P are tested and certified for safe lifting, protecting your team and your business with compliant stillages that are made to last.

Why should I choose a stillage that’s Made in Britain?

MC&P’s standard and custom stillages are Made in Britain at our factory in St Helens, Merseyside. Shipped directly from our factory without expensive shipping costs or lengthy delays, stillages made by MC&P offer fantastic value for money and get to work straight away, without the need for self-assembly.

Stillages Made in Britain by MC&P include:

- Sheet-sided and mesh-sided steel stillages

- Crane lifting stillages

- Lockable stillages

- Gas bottle cages and stillages

Choose stillages Made in Britain from the UK’s biggest online stillage range!

UK-based Metal Cages & Pallets has been manufacturing and supplying stillages that are Made in Britain for 35 years.

Our engineering experts have developed a huge range of stillage, cages, pallets and handling products, designed and engineered to suit a wide range of industries spanning manufacturing, retail, construction, infrastructure, logistics and many other sectors, for clients including BAE Systems, Network Rail and Balfour Beatty. We also serve small and medium-sized businesses across the UK, many of which have become long-time customers.

We tackle even the trickiest stillage design challenge, and although we have an extensive off-the-shelf catalogue of standard stillages, we enjoy designing and engineering new, efficient stillages to suit ever-changing business needs.

Order strong, tough & heavy-duty metal stillages made by MC&P today!

Need stillages that are made to last, whatever you throw at them? Order stillages online or get in touch to speak to our experienced team about our metal stillages, cages, pallets, racks and handling products range.

Collect from us in St Helens (10 mins from the M6 junction 23 or 24), or we’ll deliver your metal stillage throughout the UK.

We’re NOT A CATALOGUE COMPANY. Products are manufactured by our in-house engineers, with trade prices offered on our full stillage range. Ordering 40 or more stillages or other products? Contact us for a quote and a 40+ unit bulk-buy discount.

Contact us