What does LOLER stand for?

What does LOLER stand for?

LOLER stands for the Lifting Operations & Lifting Equipment Regulations 1998.

LOLER places duties on people and organisations who own, operate or control lifting equipment to ensure that equipment used for lifting is fit for purpose, appropriate for the task, suitably marked and undergoes periodic “thorough examination” by a competent person to maintain LOLER standards.

You should know what LOLER stands for, understand and comply with LOLER if your organisation owns, operates or has any control over lifting equipment, ensuring that, when you carry out any activity involving lifting equipment, you:

- Plan lifting operations properly

- Only use people to carry out such activity who are sufficiently competent

- Supervise your people appropriately during any relevant lifting activity

- Ensure all activity is carried out safely

What lifting equipment does LOLER apply to?

LOLER applies to “lifting equipment”, defined as meaning “work equipment for lifting and lowering loads”.

LOLER encompasses lifting accessories and attachments used for anchoring, fixing or supporting equipment, such as crane lifting hooks, straps and chains. Examples of lifting equipment that LOLER applies to include:

- Overhead cranes and supporting runways

- Vehicle tail lifts and cranes fitting to vehicles

- Telehandlers and forklifts

- Lifting accessories

Lifting accessories include:

- Fibre or rope slings

- Chains

- Hooks

- Eyebolts

- Spreader beams

Who needs to understand what LOLER stands for & what it applies to?

LOLER applies to every employer, self-employed person and organisation that owns, operates or controls lifting equipment for use at work. It’s essential that anyone providing, operating or controlling the use of lifting equipment knows what LOLER stands for, how it applies and the potential implications of not complying with LOLER.

Lifting operations are a major cause of accidents in the workplace, leading to incidents and injuries including falls from height, injured and crushed limbs, fatalities, and damage to or loss of property. LOLER and safe lifting equipment play an important role in preventing avoidable accidents.

LOLER applies to organisations & industry sectors including:

- Construction

- Warehousing

- Transport & logistics

- Manufacturing

- Engineering

- Agriculture

- Property & facilities management

- Events & entertainment

- Local authorities

- Forestry & environmental management

- Waste management

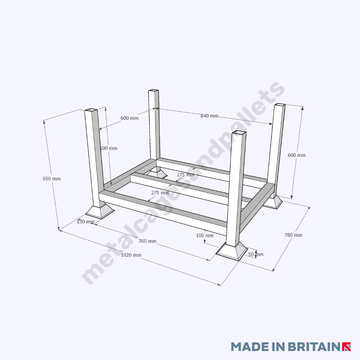

LOLER & lifting stillages safely

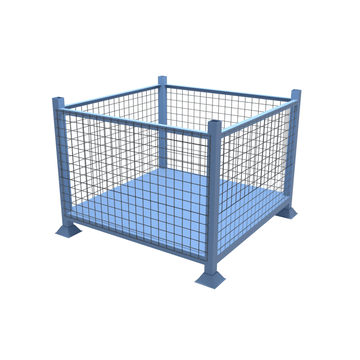

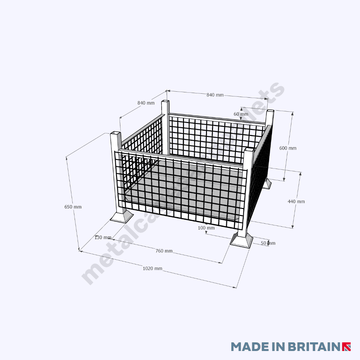

Stillages are heavy, bulky and must be loaded, moved and lifted safely, whether empty or laden.

Stillages used for lifting by crane are LOLER tested by MC&P for reassurance that they are robust and safe to use when handling laden or unladen stillages by crane or telehandler.

If stillages are not to be lifted by crane, they may be considered part of the load and, if so, would not be subject to examination and inspection under LOLER. “Loads” defined under LOLER include any material, people or animals that are lifted by the lifting equipment, such as:

- Loose bulk materials

- Sacks, bags, pallets and stillages

- Single or separate items, such as concrete blocks or building materials

- Machinery and permanently attached lifting eyes

- Skips and lifting lugs attached

How can I move my stillage safely & efficiently without lifting it?

If you need to move stillages around your workplace – for example, a warehouse, manufacturing or engineering facility – many stillages designed by MC&P can be specified with castor wheels instead of stackable feet, allowing you to move heavy, bulky loads freely without the need to lift your stillages.

Castor wheels are sturdy and strong. Standard castor wheels accommodate a load capacity of 750KG. Need more? Upgrade to heavy-duty castor wheels for a 1000KG capacity.

How does MC&P LOLER test crane lifting stillages?

MC&P has designed and engineered a range of crane lifting stillages that undergo thorough examination.

MC&P is authorised as a “competent person” under LOLER to carry out thorough examinations of stillages and lifting accessories.

LOLER testing of crane lifting stillages by MC&P includes checks to:

- Condition and structure of the stillage

- Safe Lifting Weight (“SWL”) markings clear and securely attached to the stillage

- Serial number markings clear and securely attached to the stillage

- Stillage feet structure and welds

- All welds of the stillage to ensure they are complete

- Any cracking of welds

- Stillage floor plate

- Lifting points, including lifting eyes

LOLER-tested crane lifting stillages by MC&P

MC&P’s heavy duty crane lifting stillage range is strong, tough and LOLER-tested, supplied to customers who rely on certified, hardwearing crane lifting stillages that help their organisations to comply with LOLER and operate safely.

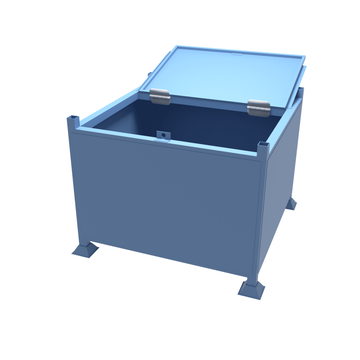

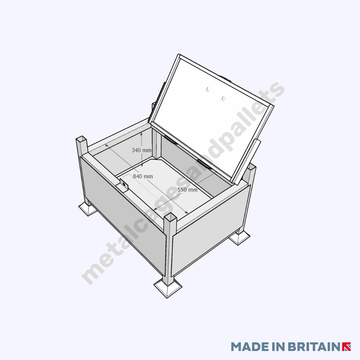

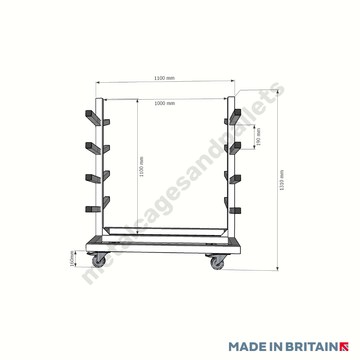

Explore our LOLER-tested crane lifting stillage collection!Crane Lift Stillage with Solid Sides

An MC&P bestseller, the Crane Lift Stillage with Solid Sides is used by organisations in construction, scaffolding and engineering to safely carry materials and parts to upper floors and areas where teams are working at height. Every Crane Lift Stillage with Solid Sides is LOLER tested before dispatch by MC&P’s certified team.

From £295.00

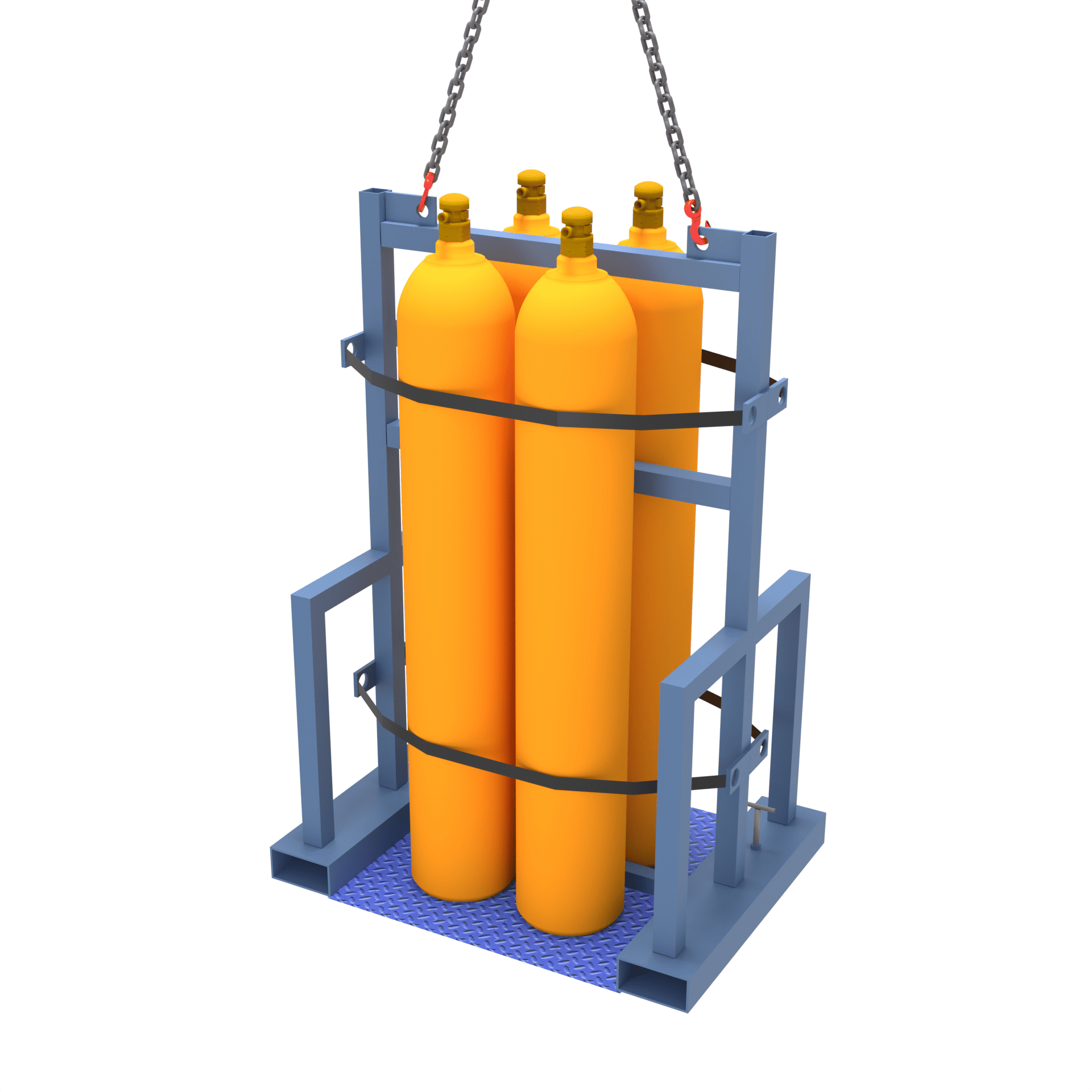

Crane lifting gas bottle handler

Working at height using argon or other gases? Safely handle and lift argon gas bottles and cylinders by crane with MC&P’s heavy duty, LOLER-tested gas bottle handler. Carrying up to 4 argon-sized gas bottles, the gas bottle handler is a tough, one-piece construction product manufactured from box section steel. 2 ratchet straps are included to secure your gas bottles during handling.

From £799.00

What happens if I don’t comply with LOLER?

Failing to understand what LOLER stands for, what the regulations state and how they apply to your organisation may carry serious implications for you and your organisation. For example, failure to comply with LOLER may lead to:

- Risk of damage, accidents and injuries, and even fatalities

- Risk of improvement notices, prohibition notices or even prosecution by the Health & Safety Executive

- If an accident or incident occurs, you may face civil liability and claims for compensation

- Operational interruptions, downtime, damage to equipment or partial closures, resulting in loss of income and profits

Explore what LOLER stands for & find out more about LOLER tested crane lifting stillages by MC&P

MC&P has produced this helpful guide to LOLER for stillages, explaining more about what LOLER stands for, how it applies to lifting stillages, and how we test our crane lifting stillages.

Not sure what you need? Just browse our crane lifting stillage collection to find LOLER-tested stillages that meet the needs of your organisation.

Can’t find what you’re looking for? Whether you need a crane lifting stillage that’s a different size, shape or carries other features, MC&P designs and manufactures custom stillages for customers with bespoke requirements.

Order LOLER-tested crane lifting stillages from MC&P today!

Need crane lifting stillages that are built to last, whatever you throw at them? Order crane lifting stillages from MC&P online, or get in touch to speak to our experienced team about our metal stillages, cages, pallets, racks and handling products range.

Collect from us in St Helens (10 mins from the M6 junction 23 or 24), or we’ll deliver your crane lifting stillages throughout the UK.

We’re NOT A CATALOGUE COMPANY. Products are manufactured by our in-house engineers, with trade prices offered on our full stillage range. Ordering 40 or more stillages or other products? Contact us for a quote and a 40+ unit bulk-buy discount.